belt conveyor pdf to word

Belt Conveyors for Bulk Materials - Fifth Edition - Chapter 6

2018年11月14日 The belt conveyor engineering analysis, infor- mation, and formulas presented in this manual represent recent improvements in the concepts and data which

Consulter un spécialiste

Construction and Maintenance of Belt Conveyors for

2018年4月27日 The successful design of a conveyor belt for bulk material handling begins with an accurate appraisal of the characteristics of the material to be transported. The

Consulter un spécialiste

DESIGN OF MATERIAL HANDLING EQUIPMENT: BELT

2015年4月15日 belt conveyor system can be employed for easy handling of materials beyond human capacity in terms of weight and height. This paper discusses the design

Consulter un spécialiste

Belt Conveyor, Structure and Principle Classification of

2022年10月25日 Classification There are many kinds of belt conveyors, which can be divided into two types according to the mode of transmission: roller transmission and wire

Consulter un spécialiste

(PDF) BELT CONVEYOR - ResearchGate

2022年4月14日 PDF Belt conveyor is a material transfer equipment that uses a belt (tire belt) as a transfer tool used to move unit loads (unit loads) and rainfall... Find, read and

Consulter un spécialiste

DESIGN AND SELECTING THE PROPER CONVEYOR-BELT

2013年5月9日 This paper provides to design the conveyor system used for which includes belt speed, belt width, motor selection, belt specification, shaft diameter, pulley, gear box

Consulter un spécialiste

Conveyor Belt Manual - IBT Industrial Solutions

2022年12月29日 I. Conveyor Belt Construction Conveyor belts generally are composed of three main components: 1. Carcass 2. Skims 3. Covers (carry cover and pulley cover)

Consulter un spécialiste

Belt Conveyor - an overview ScienceDirect Topics

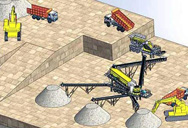

Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or on an inclined either up or down.

Consulter un spécialiste

(PDF) BELT_CONVEYORS.pdf Prabir Datta - Academia

Conveyor belts with capacity of 11000t/h and even higher can be deployed to match with higher capacity mining machinery. 3. Longer distances can be covered more

Consulter un spécialiste

Belt Conveyors for Bulk Materials - Fifth Edition -

For a given speed, belt conveyor capacities increase as the belt width increases. Also, the capacity of a belt conveyor depends on the surcharge angle and on the inclination of the side rolls of three-roll

Consulter un spécialiste

DESIGN OF MATERIAL HANDLING EQUIPMENT: BELT

2015年4月15日 The design of a belt conveyor system takes into account the followings: A. Dimension, capacity and speed B. Roller diameter C.Belt power and tension D.Idler spacing E. Pulley diameter F. Motor G. Type of drive unit H. Control mode Figure 1: Belt Conveyor Figure 2: CATIA Design of Belt Conveyor Belt Dimension, Capacity and Speed

Consulter un spécialiste

IS 11592 (2000): Selection and Design of Belt Conveyors

2018年11月15日 NOTE — The troughed angle of 15° is applicable for 2-roll belt conveyors only. 4.2.1 For return idlers, the troughing angle of 0°, 10°, or 15°, shall preferably be adopted. 4.3 Flat belt conveyor is that in which the belt runs flat on the carrying side, over an idler or a set of idlers. 1

Consulter un spécialiste

Belt Conveyor, Structure and Principle Classification of

2022年10月25日 Wire Rope Core Conveyor Belt (GB/T 9770–2013), the width of steel wire rope core conveyor belt is 800–3200 mm, and the strength range of conveyor belt is 630–7500 N/mm. The types of steel wire core belt include the ordinary conveyor belt, the flame retardant conveyor belt, the high temperature resistant conveyor belt, the

Consulter un spécialiste

Construction and Maintenance of Belt Conveyors for

2018年4月27日 The successful design of a conveyor belt for bulk material handling begins with an accurate appraisal of the characteristics of the material to be transported. The behavior of bulk materials greatly depends on the moisture content and particle size distribution of the material. Wide variations in material behavior and bulk density with

Consulter un spécialiste

Belt Conveyor - an overview ScienceDirect Topics

10.2.3.1 Belt conveyors. Belt conveyors are the most widely used and versatile mode of mechanical conveying systems employed to transport materials horizontally or on an inclined either up or down. Fig. 10.1, represents a typical belt-conveyor arrangement, with the following main components of the system: Figure 10.1.

Consulter un spécialiste

(PDF) Design of a Material Handling Equipment: Belt Conveyor System

2014年1月16日 The velocity of the conveyor belt and conveyor capacity were 1.07 m/s and 30.3 tons/hr while the effective tension of the conveyor belt and horse power required to drive the conveyor belt were 201 ...

Consulter un spécialiste

(PDF) Best Practices on Conveyor Safety - ResearchGate

2015年6月3日 In conveyor belts, fixed guards that only partially surround the danger zone take on two principle shapes: partial cages, as illustrated in Figure 2-2 and used mainly for head and return drums

Consulter un spécialiste

Conveyor Belt Manual - IBT Industrial Solutions

2022年12月29日 conveyor belt is normally referred to as the "carcass." In a sense, the carcass is the heart of the conveyor belt since it must: 1. Provide the tensile strength necessary to move the loaded belt. 2. Absorb the impact of the impinging material being loaded onto the conveyor belt. 3. Provide the bulk and lateral stiffness

Consulter un spécialiste

CONVEYOR BELTS SAFETY PROCEUDRE - Tata Power

2023年7月10日 Conveyor Belt Safety Procedure TPSMS/GSP/CONV/002 REV 01 Date of Issue: 30-06-2016 3. EXPECTED RESULTS: 3.1. Written down procedures for Operation and Maintenance of Coal Conveyors Belts. 3.2. Manage jobs being done in Coal Conveyors Belts safely 3.3. Control of incidents in Jobs related to O M of Coal Conveyors Belts 3.4.

Consulter un spécialiste

Conveyor Types and Conveyor System - MIS Belt Centre

Vacuum Belt Conveyors Vacuum belt conveyors are made by perforating the belt and drawing air through grooves in the bed of a standard conveyor. Holds flat parts of any material fast to the belt. Ideal for elevation changes or part holding. Can be used in upside down applications. Vacuum area required is designed per application.

Consulter un spécialiste

CONVEYOR BELT PREVENTIVE MAINTENANCE CHECKLIST

2020年8月11日 Modular plastic belts (MPB): 6 in (152 mm) or more of catenary sag depth. Shorten the belt in even rows (2, 4, etc.) to maintain the proper belt pattern. Remove the minimum number of rows needed to maintain the proper amount of catenary sag. • If the belt does not remain engaged or the amount of catenary sag is larger than the

Consulter un spécialiste

Thermo Scientific Belt conveyor scale handbook

2022年8月12日 A belt conveyor scale is a device that measures the rate at which bulk material is being conveyed and delivered on a moving conveyor belt. It can compute the total mass of material conveyed over a given period of time. As one of the leading manufacturers of modern belt conveyor scales, we have not only pioneered the latest state-of-the-art

Consulter un spécialiste

Checklist Conveyors PDF Belt (Mechanical) Equipment

2023年5月5日 1. Check for any damage to the belt or splice. 2. The conveyor should be locked out while making this inspection. 3. Rubber belt damage should be repaired using the hot vulcanized repair method or the cold. repair method. 4. Belt fabrics that are exposed should be properly cleaned, dried, then covered with new rubber.

Consulter un spécialiste

A Comparative Study on the Cost-effective Belt Conveyors for Bulk ...

2017年12月1日 Subject to the assumption made and the manufacturers supplied information, the study shows that the implementation of the most cost-effective multi-drive conveyor will result in equivalent annual cost savings of about 63,120 $ (USD) and 29,475 $ (USD) over the cheapest single drive and single-tandem drive contenders, respectively.

Consulter un spécialiste

Dynamic Behaviour of a Conveyor Belt Considering Non

2020年6月30日 applied sciences Article Dynamic Behaviour of a Conveyor Belt Considering Non-Uniform Bulk Material Distribution for Speed Control Fei Zeng 1,2,*, Cheng Yan 2, Qing Wu 3 and Tao Wang 1 1 Key Laboratory of Metallurgical Equipment and Control Technology of Ministry of Education, Wuhan University of Science and Technology,

Consulter un spécialiste

CONVEYORS - ABB

2021年2月16日 misalignment on the conveyor belt. ABB’s Ulf Richter referred to the fact that ABB’s digital services for material handling performance and optimisation are now available. Due to decreasing ore contents and deeper mines, continuous belt conveyors are becoming more and more important. Even in global supply

Consulter un spécialiste

Conveyor Installation and Maintenance Manual

2018年6月14日 4. MODULAR CONVEYOR EXPRESS-developed controls: MODULAR CONVEYOR EXPRESS’s liability for defects is limited to the correction of demonstrable defects that are defined and documented by the PURCHASER. D. MODULAR CONVEYOR EXPRESS shall be relieved of any obligations under the foregoing warranty as to any

Consulter un spécialiste

PUBLICACIONES TECNICAS-Descargas - CEMA

cema safety best practice 002-2016 – e-stop application guide for unit and bulk belt conveyors ... cema safety best practice 004-2015 – supplemental guarding for unit handling conveyors (pdf) cema safety best practice 005-2016 – “design application of personnel barriers adjacent to elevated unit handling conveyors” (pdf)

Consulter un spécialiste

Design of material conveying by variable pipe conveyor

conveyor belt with the marking ECOTUBELT F1: P 500/2 4+2, F1 meets the maximum tensile force in the conveyor belt. 3 The spacing of idler rollers The spacing of idler rollers depending on the diameter of the rolled up pipe conveyor according to the [6] is presented by the following comparative table.

Consulter un spécialiste

Article aléatoire

- prix de materiel de patisserie doccasion en Maroc

- concasseur amende de machine

- meilleur crushe pour les mines d'or

- acierie generale ltd asaba

- rouleau et refroidissement de la bande système de laminoirs

- briques de beton usine de fabrication moulin

- Carrière de pierre en Chine

- broyeure de verre

- broyeur a bentonite portable a louer qatar carbone

- de concasseur a machines des additifs et des adjuvants pour beton

- broyeur de pierres occasion à vendre à tirunelveli

- pdf broyeur a boulets moulin

- minier concasseur à minerai comment cela fonctionne:

- Gravier unités de concassage inde

- machine de separation d'argent

- Broyeur à ciment Spécifications

- les inconvenients d'un giratoire de concasseur a machines

- produits de ciment equipements

- la taille des agrégats grossiers pour le béton

- abrasif broyeur de matière

- Canada zinc broyeur à la mine

- machine à broyeur à grains

- concasseur plastique avec vis sans fin

- pierre convoyeurs de concassage ceinture à vendre

- définition de criblage

- tapis roulant caoutchouc

- Concasseur Penggilingan usine

- triturador de pedra planta em rajisthan

- alimentateur vibrant prix

- fournisseurs de marbre londres